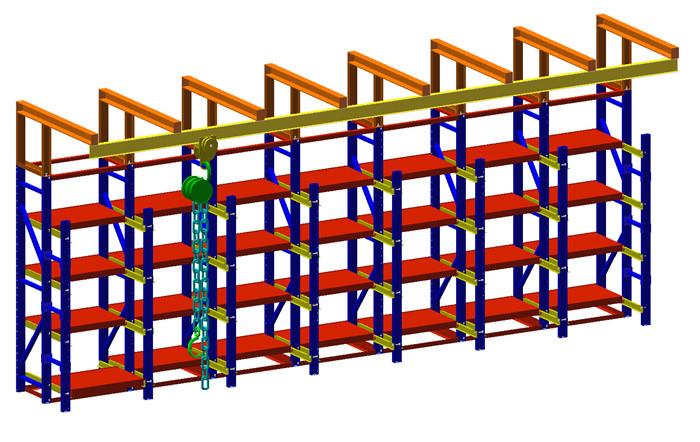

Radio Shuttle Rack

Radio Shuttle rack is a racking framework with high-thickness stockpiling including racking and electrically controlled bed sprinters which work with forklifts. This high productive stockpiling arrangement gives another choice to greatest utilization of distribution center volume.

Description

Radio Shuttle rack is a racking framework with high-thickness stockpiling including racking and electrically controlled bed sprinters which work with forklifts. This high productive stockpiling arrangement gives another choice to greatest utilization of distribution center volume.

Features

- High thickness stockpiling.

- FIFO or FILO.

- High throughput proficiency.

- It is Much better than Drive security.

- Adaptable industry.

- Big amount however little categories:Foods,beverage,chemistry,tobacco,etc.

- Cold storage: Effectively diminish working time, better productivity, and security.

- Expiration control: Strict impediment of groups of goods, which requires FIFO.

- Volume increasing: Maximum utilization of restricted space of distribution centers.

Advantages

- More limited dump times for beds. The Radio Shuttle modules (RSM) recover the beds and carry them to the walkway entrance so the forklift doesn’t need to enter the path.

- Great for profound path stockpiling

- Allows the capacity of various reference numbers per module and along these lines a bigger number of putting away references

- Lower danger of mishaps

- Reduced dependence on forklifts inside paths forestalls rack harm

- By adding more RSMs, the progression of approaching and active products increments

- Optimizes space by compacting beds with various widths inside the channels.