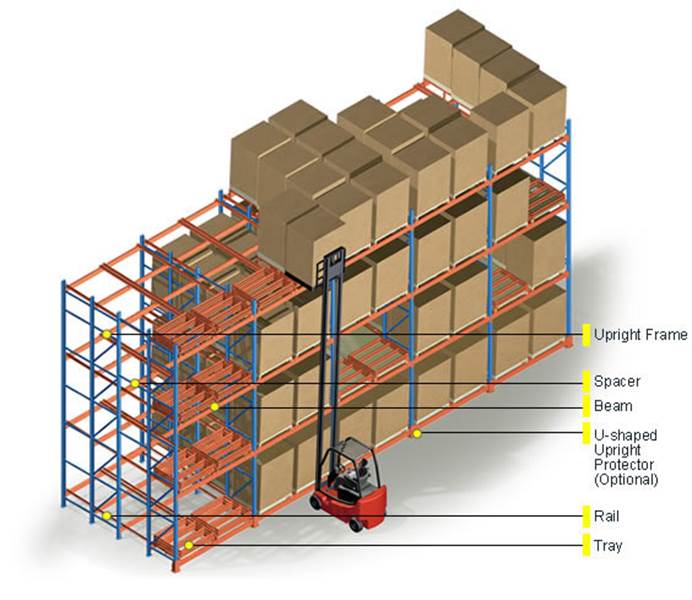

Heavy Duty Push Back Rack System

Push back rack is a first in-last-out capacity framework, suits for bringing together palletized products. Push back rack framework is a high thickness stockpiling framework, it can utilize the distribution center spaces, so it saves space.

Push back rack is a first in-last-out capacity framework, suits for bringing together palletized products. Push back rack framework is a high thickness stockpiling framework, it can utilize the distribution center spaces, so it saves space. In a similar region, push-back rack can store a lot more products contrasting and traditional bed racks. Push back rack framework needn’t bother with forklift going into the racking paths, so upgrade security factor for forklift administrator. 1 trolley system can take 2 pallets position in deep direction, 3 trolley system can take 3 pallets position in deep direction, 3 trolley system can take 4 pallets position in deep direction. These three systems are our normal standard, of course, we can also make 4 trolley systems, even 5 trolley systems for special requirements.

Benefits

- Better utilization of distribution center space – push back presents to 90% more item stockpiling than particular rack frameworks.

- Store an assortment of SKUs on various degrees of paths for simple item access.

- Interlocking trucks assist with forestalling risky sticking and exorbitant item harm.

- Up to 300% more selectivity than drive-in racks makes push back more flexible for a more noteworthy number of SKUs.

- High stockpiling thickness combined with selectivity for quicker pick rates.

- Color-coded trucks for simple visual stock.

- A large focus for stacking and dumping.

- Maximizes space usage by filling the upward shape.

- “Last in, first out” stock.

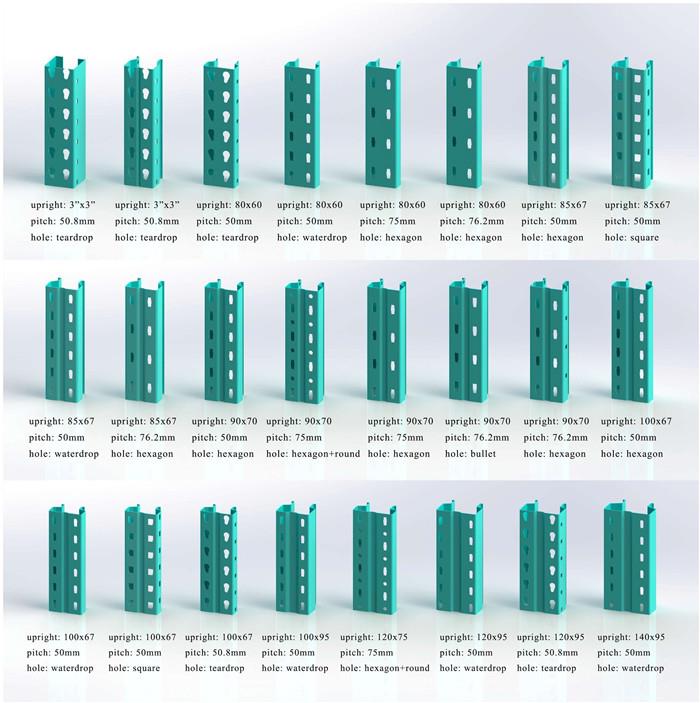

Frame

- Frames incorporate every one of the components required for getting together: supporting, base plate, and nuts and fasteners.

- Blue epoxy coated(RAL5005).

- Standard statures: From 800-1500mm.

- Adjusted by 50mm or 75mm pitch.

- Choose 90*70*2.0mm at any rate.

- Frame profundity is bigger 50mm than bed profound. Column spacer length is the same as the casing profundity.

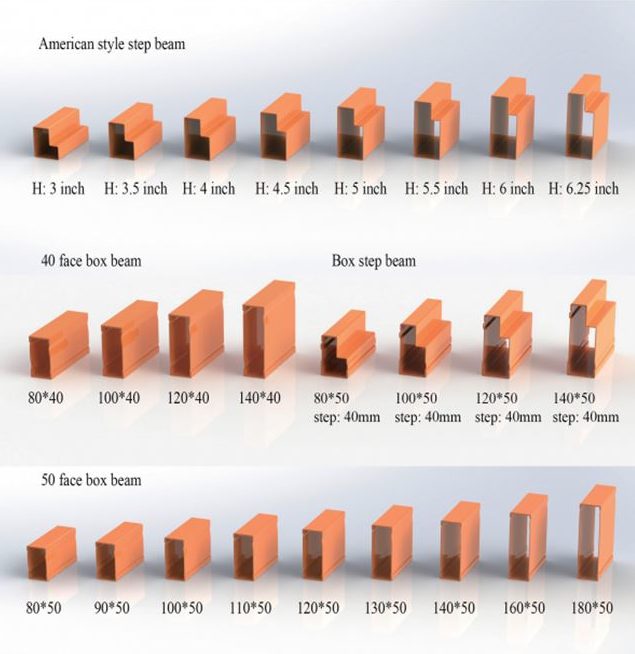

Beam

- The high burden limit is up to 1500kg.

- Made with the best steel.

- Orange epoxy coated(RAL2004).

- Boltless association with 3 or 4 connector snares.

- A self clasping pins for every shaft to forestall inadvertent dislodgement.

- Powder covering finish

- For the first bar, we will pick essentially 120*50*1.5mm box shaft, on the grounds that in the principal bar, likewise need to weld point steel. For the center pillar and back shaft, we additionally need to pick a case bar as indicated by the stacking limit, yet this multitude of bars has many interfacing plates.