Drive In Racking System With Powder Coated For Warehouse Storage

Drive-In rack, being quite possibly the thickest racking option accessible, gives you the greatest utilization of accessible space. Drive-In is a high thickness, LIFO (last bed in, first bed out) racking framework that has many fewer passageways, which considers better 3D square use. You can amass to 75% a larger number of beds than a particular framework.

Drive-In rack, being quite possibly the thickest racking option accessible, gives you the greatest utilization of accessible space. Drive-In is a high thickness, LIFO (last bed in, first bed out) racking framework that has many fewer passageways, which considers better 3D square use. You can amass to 75% a larger number of beds than a particular framework.

Drive-In Rack and Drive-Thru racking are terms that are frequently utilized reciprocally. In certain conditions, it tends to be hard to separate between the two. Commonly, Drive-In racking expects administrators to crash into the racking framework from one side and eliminate beds from a similar passage point. Some Drive-In rack frameworks have a divider or are generally shut at the furthest edge.

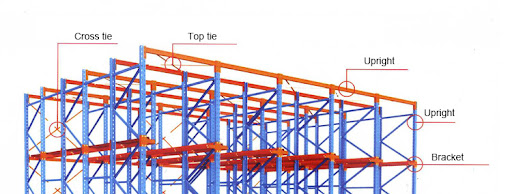

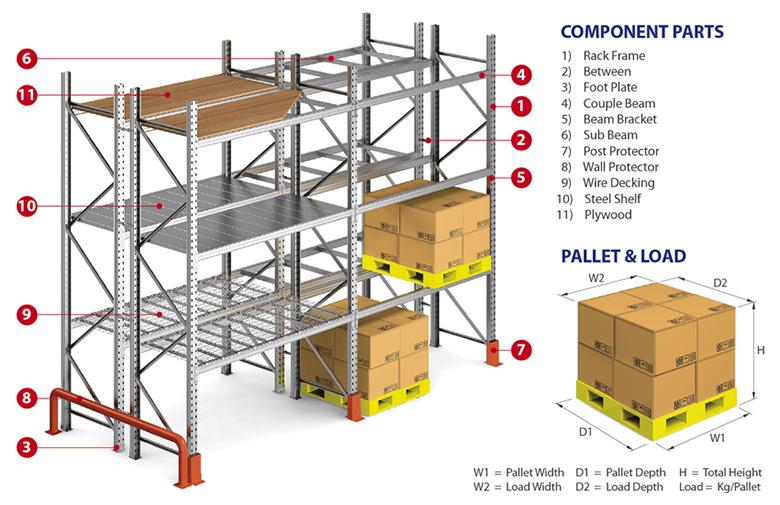

Components

- Frame

- Pallet rail

- Double side arm

- Single side arm

- Top beam

- Back beam

- Double side row spacer

- Single side row spacer

- U shaped upright protector

- Top bracing

- Back bracing

- Ground rail

How Does Drive In Rack Work?

Forklifts stack and dump beds by entering the rack structure through the front of the sound, which is made conceivable by the absence of conventional bed racking pillars. All things being equal, drive-in rack utilizes rails that run along within the narrows (from front to back), in which the beds lay on. Being that this framework is LIFO, the last bed stacked will be the first dumped. Floor mounted aide rail is a suggested choice for drive-in rack frameworks to diminish outline harm from forklifts.

Drive-In rack administrators should be exceptionally mindful so as not to harm the bed racking. Since beds are put away so thickly and a driver should enter the bed racking framework with just a little leeway on one or the other side, a Drive-In rack framework should be checked for harm oftentimes. When bed rack harm is seen it should be accounted for and appropriately fixed or supplanted. A severe wellbeing tenet should be clung to with a Drive-In rack framework.