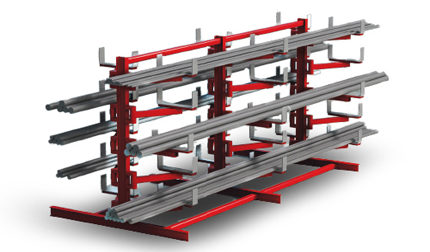

Heavy Duty Cantilever Rack For Long Pipe Storage

The cantilever rack is fundamentally a rack made out of a segment, a cantilever shaft, an interfacing bar, and such, and is described in that the cantilever structure with a forward reach has a lightweight and a solid conveying load, and can enormously work on the capacity of unstandardized or long bar materials.

The cantilever rack is fundamentally a rack made out of a segment, a cantilever shaft, an interfacing bar, and such, and is described in that the cantilever structure with a forward reach has a lightweight and a solid conveying load, and can enormously work on the capacity of unstandardized or long bar materials. Proficiency and work productivity, the cantilever can be single-sided or twofold-sided.

In the wake of adding wood sheets or steel gratings, it is especially reasonable for little and low-thickness stockrooms with advantageous administration and open vision. Generally utilized in mechanical handling and building materials grocery store industry.

Characteristics

- The utilization of square cylinder creation: cantilever racks as per the comparing cantilever layer load necessities, first select the square cylinder that meets the prerequisites of the layer load, cut into the necessary size, in a welded non-slip plate, the opposite finish of the welded association U-molded segment connector Made from.

- Utilizing C-molded steel creation: Cantilever racks as per the comparing cantilever load necessities, the primary determinant of C-shaft particulars, chosen after the two C-formed steel butt welding, subsequent to welding in a welding slip plate, the other welding Connect the U-molded post connector.

- The cantilever rack section and the segmented sheet are associated with an interfacing pole, and the interfacing pole is by and large made of a rectangular cylinder. To expand security and strength, add a level iron back on the associating pole to pull the uncommon puller to fix the section solidly.

3). All cantilever rack parts are semi-completed after the creation is finished and will be powder covered through the last cycle. Before showering, a shot impacting machine was utilized to eliminate oil and rust, trailed by splashing. After the consummation, and afterward do standard bundles, convey the racks.

Advantages

- The utilization of square cylinder creation: cantilever racks as per the comparing cantilever layer load prerequisites, first select the square cylinder that meets the necessities of the layer load, cut into the necessary size, in a welded non-slip plate, the opposite finish of the welded association U-molded segment connector Made from.

- Utilizing C-molded steel creation: Cantilever racks as per the comparing cantilever load prerequisites, the principal determination of C-pillar particulars, chosen after the two C-formed steel butt welding, subsequent to welding in a welding slip plate, the other welding Connect the U-formed post connector.

- The cantilever rack section and the segmented sheet are associated with an interfacing pole, and the associating pole is by and large made of a rectangular cylinder. To expand security and strength, add a level iron back on the associating bar to pull the unique puller to fix the section immovably.

- The cantilever rack series takes on blend type, dismantling, transportation, change, and development, and so forth

- Movable segments can be utilized to change the separation among segments and increment or decline the number of segments as per real requirements.

- Can completely further develop the space usage, with the goal that the distribution center material administration normalization and stacker crane or forklift coordinating, not exclusively can further develop the material dissemination productivity, lessen capacity costs, increment financial effectiveness, yet additionally can work fair and square of automation of materials flow, Reduce workforce and work on working conditions.

- Cantilever rack length can be free combinated as per the site conditions.