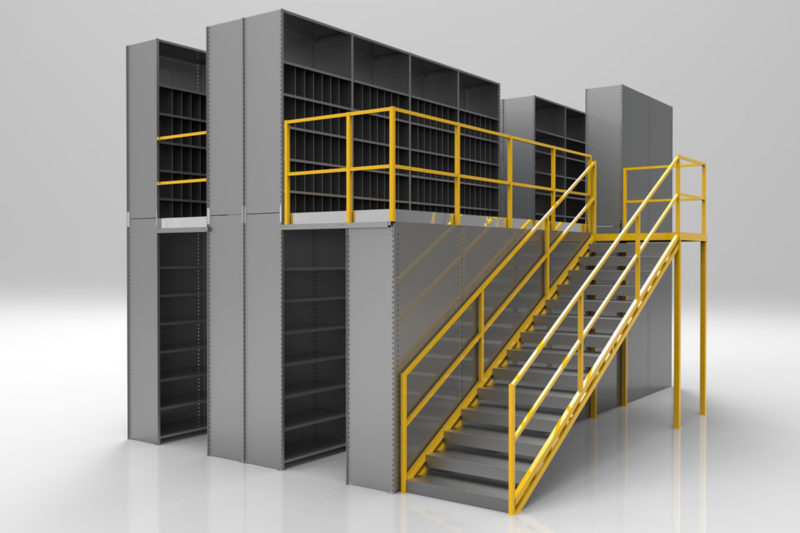

High Quality Mezzanine Shelves

The Mezzanine Shelving System will assemble a center space on existing destinations or racks to build an extra room. It tends to be utilized in a few story lofts for light froth and little and medium freight.

Mezzanine racking frameworks regularly utilize medium racks or substantial racks as the essential help and floor (which rack is chosen dependent on the absolute weight of the rack unit). The floor is generally made of cold-moved steel floor and designed steel floor. Or on the other hand steel grille floor.

The Mezzanine Shelving System will assemble a center space on existing destinations or racks to build an extra room. It tends to be utilized in a few story lofts for light froth and little and medium freight. A wide assortment of little clusters of merchandise, counterfeit admittance to products. Products are typically shipped to the second and third floors by forklifts, water-driven lifts, or cargo lifts, and afterward moved to an area using a light truck or pressure-driven bed truck.

Classification:

- Medium-sized mezzanine shelves: The shelf infrastructure uses medium-sized shelves. The shelf floor adopts a special floor for the mezzanine shelf, and the floor panel adopts an interlocking structure. Support beams are erected below the floor.

- The specifications of the medium-sized mezzanine shelf columns are 60×50×1.5mm or 70×50*1.5 special shelf column profiles. The high-quality steel strip is passed through molding, automatic rolling mill, punch punching, and then cut off according to customer-specified height. Column brackets and connecting beams are made of high-quality cold plates that are bent and punched.

- The specification of the heavy-duty racking column is a 90×70×2.0mm special heavy-duty shelf column profile. The cross beam adopts a cold-rolled p-type closed beam, with specifications of 50×30, 60×40, and 80×50. It is a standard product that is specially produced for shelves in the cold bending industry. After repurchasing, according to the customer’s size, the welding shelf is connected with a special column to grasp and polish to form a semi-finished product.

- After the production of all the shelf parts, the last shot blasting machine is required to perform shot blasting, rust removal, and surface spray treatment. After completion, it can be packaged and shipped.

Features

- Mezzanine racks are rack supporting racks that partition the stockroom into a few spaces of an exceptional rack.

- Typically, 2-3 stories, steps, and merchandise lifts are given.

- Appropriate to the high stockroom, little freight, manual access, enormous capacity volume.

- The creation and establishment of the mezzanine rack is exceptionally straightforward and fast, the get together is basic, no screws, determinations can be modified, multi-reason plate discharge, simple to utilize, is the best option for enormous and medium-sized ventures decide to store rack stockpiling

- Mezzanine racks are reasonable for putting enormous, medium, and little pieces, just as items with uniform details, simple to order, advantageous, quick, and dependable.

- The vast majority of the heap limit of this rack is 800KG. This stage can save space and significantly lessen the space squander.

- Different determinations can be modified. This rack is utilized in coordination and processing plant undertakings with huge use, appropriate for huge and medium-sized distribution centers.